|

CHARACTERISTIC |

UNIT |

S-460 |

S-650 |

S-800 |

|

SINTERING CHAMVER Dimensions |

mm |

¥õ460*470 |

¥õ650*1020 |

¥õ800*1100 |

|

WARKING ZONE |

mm |

100*100*100 L |

240*240*500 L |

350*300*550 L |

|

CHARGING Capacity |

Kg |

20 |

40 |

80 |

|

MAX. TEMPERATURE |

¡É |

1000 |

2000 |

2000 |

|

HEATING ELEMENT |

|

Kantal |

Graphite |

Graphite |

|

THERMO-COUPLE |

|

Inconel. KType |

WRe5-26 |

WRe5-26 |

|

CONTROLING |

|

|

PID |

|

|

COOLING SYSTEM |

Cooling in Vacuum and Inert Gas |

|||

|

UTILITIES |

|

|||

|

Power required |

V |

3¥õ 380 or 3¥õ 220 |

||

|

Cooling Water |

Kg/§² |

2 |

2 |

2 |

|

Water capacity |

I/min |

100 |

150 |

250 |

|

Compressed air |

Kg/§²G |

7 |

7 |

7 |

|

Power capacity |

KVA |

10 Approx |

40 Approx |

60 Approx |

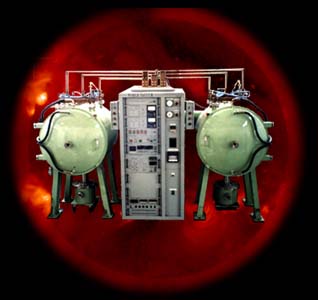

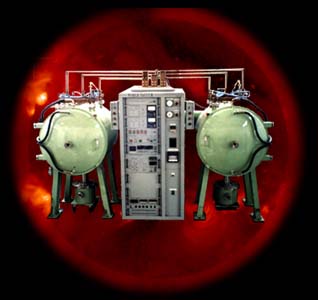

TWO CHAMBER Type

(Max. 1000¡É)